1. Rebar Straightening Machines Videos

MY2-5 works for Ø2mm~Ø5mm wire coil,scrap wire, cold drawing wire; not for hard wire or spring wire;

Electric motor 3Kw

Straightening speed 20m per minute

Machine Weight 100kgs

Dimension size 67*50*85cm

MY5-12 works for Ø5mm~Ø12mm scrap steel,wasted steel bar,crooked steel bar and so on..

Electric motor 5.5Kw

Straightening Speed 20m per minute

Machine weight 330Kgs

Dimension size 118*65*78cm

MYH6-14 works for Ø6mm~Ø14mm round bar, scrap rebar, used rebar, rebar coil and so on..

Electric motor 9.5Kw

Straightening Speed 35m per minute

Machine weight 850Kgs

Dimension size 150*125*90cm

YC6-14 works for Ø6mm~Ø14mm round bar, scrap bar, used bar, and so on..

Electric motor 7.5Kw

Straightening Speed 25m per minute

Machine weight 700Kgs

Dimension size 122*82*125cm

YC16-24 works for Ø16mm~Ø25mm round bar, scrap bar, used bar, and so on..

Electric motor 15Kw

Straightening Speed 20m per minute

Machine weight 900Kgs

Dimension size 152*92*125cm

MY10-25 works for Ø10mm~Ø25mm round bar, scrap bar, used bar, and so on..

Electric motor 15Kw

Straightening Speed 20m per minute

Machine weight 900Kgs

Dimension size 150*90*135cm

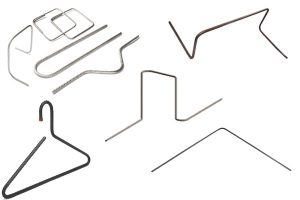

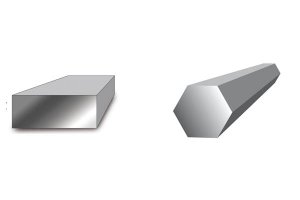

2. Materials For Processing, Yes Or No

Yes, items are wire pieces,wire coil,scrap rebar,wasted rebar,rebar coil,rebar wire and so on;in various shapes

No, stuffs are not available: flat, angle, tubes….

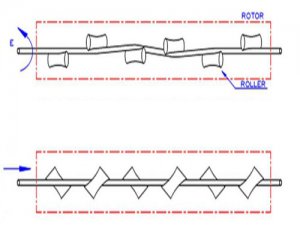

3. Machine Work Principle

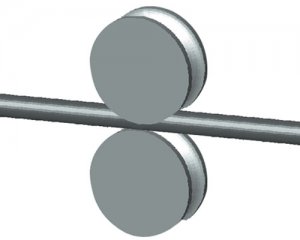

This group machines are the type rotor straightening system with rollers

It produces a very good straightness as advantage, but it generates too much heat when the system rotor straightening in high speed, due to friction, and it produce little damages to the rebar surface, little scratches. So it can remove rebar rust surface deservedly.

Machine Model: MY2-5 MY5-12 MYH6-14

This grouped machines are the type two rollers configuration, one pair.

It produces a common straightness, but advantage is simple operation, it’s easy to straight different diameter rebar with easy operation, very good for recycling scrap rebar from demolition.

Machine Model:YC6-14 YC16-25 MY10-25

4. Issues Related to Price & Cost

How much the price?

Prices as low as to US $450~, the price is FOB, if we know your port, we can also check CNF or CIF,

How much the cost I have to pay?

If you are not familiar with import business, we can help you calculate DDP(delivered duty paid ) to you, here DDP means the total cost you have to pay, as machine arrive your hand.

5. Who Are The Users?

Steel mill plant: it comes out crooked rebar always,

Scrap metal recycling station: straightening scrap rebar for recycling, then used for not important area except buildings

Rebar distributor: straightening which crooked

6. About Us, Company Overview

Be founded at 1999,started by four staffs and a small plant,

By this time, we own tens of staffs and a vast ground (15000 square meters),annual production output thousands sets,annual value output tens of millions, products cover many kinds, such as rebar bending machine,rebar cutting machine,rebar straightening and cutting machine, rebar scrap straightening machine,radius bending machine,pipe straightening machine and others transaction…

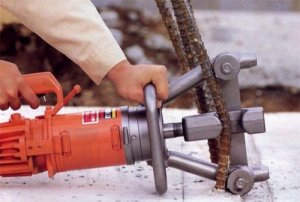

7. Compare With Portable Rebar Straightener

This portable type, used for straightening the rebar hook that inserted in concrete bases, we call it after-use rebar,

While those above rebar straightening machines used for straightening before-use rebar

9. Much More Images Media

We show more rebar straightening machines images on the time delivering customer’s order, More Images

Leave A Comment