Rebar Cutting Machine:What is It and How to Use It (Steps By Steps)

What is rebar? Concrete used in construction may be strong in compression but it is weak in tension.

To fill this deficiency, steel is used. The steel used in concrete is called Reinforcement steel. The steel bars are also called rebar. These rebars are of different grades and sizes depending upon the requirement.

Contents

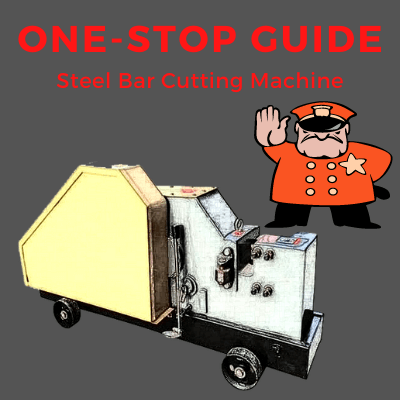

What is a Rebar Cutting Machine

When manufactured, these bars are long in length and are required to be cut. One of the machines used to cut these bars is called rebar cutting machine.

It has a high efficiency of cutting rebar. It is a 450-600 Kg heavy-duty machine with wheels, making it portable.

Professional companies use this machine to cut rebar at the site cleanly and quickly. Not like other machines, it does not work on the principle of cutting through a saw.

There are many variations of the machine and each machine has a separate capacity of rebar it can cut.

The machine consists of a cutting clutch that allows the user to control the process.

Support brackets are provided in the machine to support the cutting process safely.

The machine has a lifting ring that allows you to carry it anywhere you like.

This is one of the safest and fruitful investment for a company. It is better than buying cheap tools for rusty works.

rebar cutting machine for sale

How Does it Work?

Some people might ask how the machine works?

How is it able to cut through the bar so easily?

What is the principle behind it?

This machine is unlike conventional saws or cutters. Rebar cutting machine does not use a normal thin cutting blade, it uses an alloy dull blade to cut through the rebar.

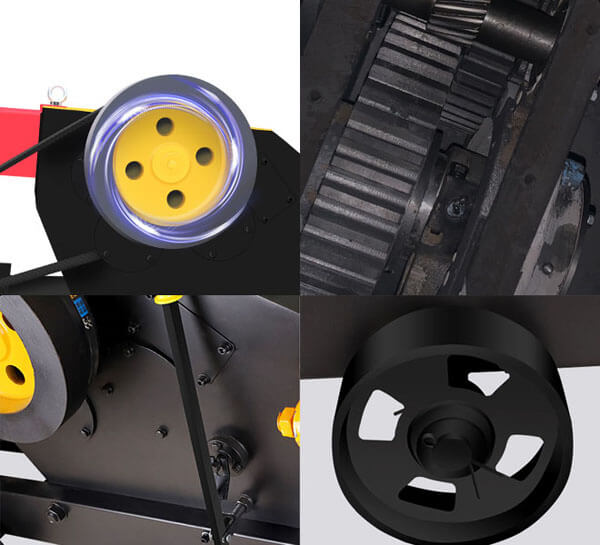

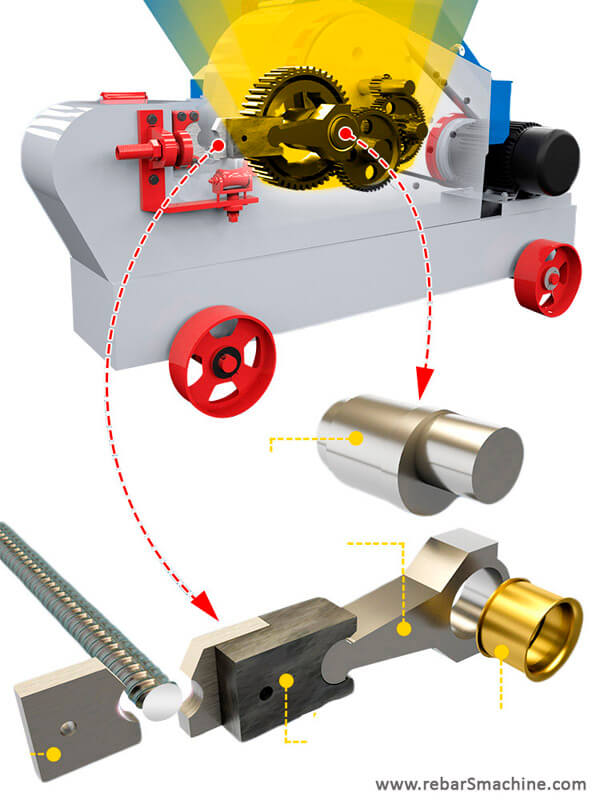

The rebar cutting machine works on the principle of pulleys, gears, and electric motor.

It consists of a strong electric motor. The electric motor is connected to a large pulley through a V belt. The electric motor makes the pulley move. The pulley then turns several connected gears inside the machine.

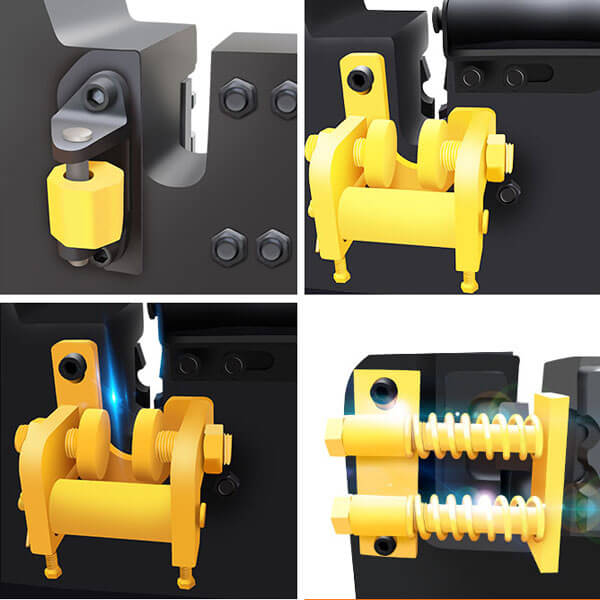

The resulting torque drives the crankshaft. The crankshaft then drives the connecting rod to move the cutting blade.

One blade is fixed while the other blade is moveable. The bar to be cut is placed in between them.

The force generated by the motor is so much that the blades are able to cut the rebar in two. This mechanism is also called Grip and Slice.

The U-shaped support between the blades grips the bar. The moveable blade then moves from its slot and presses on the bar.

This cuts the bar cleanly at the point of contact with the blades.

How to Use It?

So you are a construction company that recently bought a rebar cutting machine, but don’t know how to operate it?

Just buying a rebar cutting machine does not mean that all your problems are solved. The workers must know how to operate the device.

Wrongly operating the device may hurt the machine or the operator. But have no worries, because the entire operation is as easy as anything you know.

In this guide, we will tell you how to use or operate the machine

Step 1: The first step in the operation is to find an empty room to set up the machine. The room will act as a small steelyard. This is done to avoid any safety hazards or accidents.

Step 2: Next you connect the machine with a stable source of electricity. Make sure that the wires are properly covered someone does not trip on them. Since it runs on oil, you have to carefully pour oil in the oil opening as well.

Step 3: Use a safety checklist to see if all precautions are made. The machine can prove to be dangerous if precautions are not made. Remember to stand away from the machine when using it.

Step 4: A long stick-type handle can be found on the side of the machine. It is called a cutting clutch. It moves the blade every time you pull it. Adjust the cutting clutch to your desired length to control the process easily.

Step 5: Before you start cutting, mark your bars at points you want to cut. Now, safely place the steel bar inside the U-shaped grip and stand at least 2 feet away.

Step 6: Pull the cutting clutch. The moveable blade will slide towards the fixed blade and cut the bar in between. The motor gives enough energy to the blade to cut through the bar easily.

Step 7: The same process is repeated every time. Next time you can repeat the process for a greater number of bars as well.

Leave A Comment